Explain Difference Between Die Casting and Sand Casting

Then a plunger is used to apply pressure to the metal. What is the difference between true centrifugal casting and semicentrifugal casting.

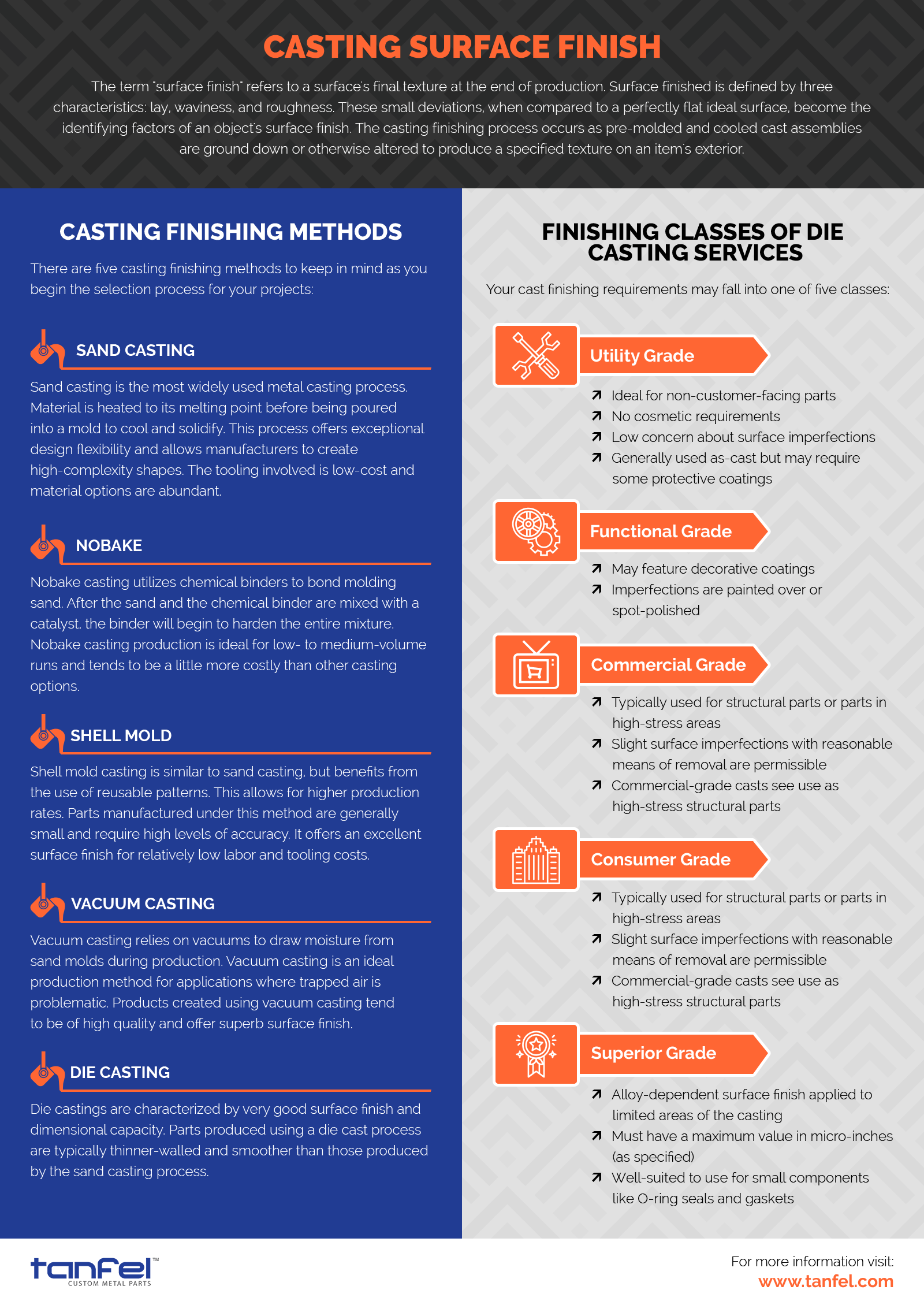

Casting Surface Finish Sand Casting Die Casting More Tanfel

Difference between a-gps and glonass-difference between microwave oven-difference between rs232 rs422 rs485-difference between ac dc motor-difference between rtd thermocouple-die casting die design-pressure die casting die design-mini cooper die cast-pressure die casting machine-die cast car model-.

. In permanent mold casting metal flows into the cavity from a reservoir. Molten metal is poured into the sand mold then following solidification and cooling the sand is broken away and the casting is removed. When a casting is going to be hollow sand or metal called the.

Although there are some variations in technique the major difference between die casting and injection molding is that die casting uses some kind of metal often an aluminum alloy as the raw material while. The melt passes through a valve into the casting chamber where it is pressed at high. In Sand Casting Process the Mould is made up of Sand whereas in.

When the metal cools and becomes solid you have a product that has just been manufactured. The pressure helps the liquidus metal to reach the cavity. Sand casting takes sand as the main mold making material while die casting usually uses steel to manufacture the die casting mould.

The biggest difference between die casting and sand casting is the material used to make a mold. A one-time sand mold is produced which may contain one or more impressions of the part. Both die and sand casting are widespread efficient and highly useful casting methods so it can be difficult to specify one from the other when concerning your project.

Below we point out the benefits of each process as well as which applications each are used for. Finally you open the die and remove the shot. Lets clear up the casting confusion with a cursory overview.

Die casting is a more preferred solution for medical device projects while choosing. You then cool the diemold with internal cooling lines and die spray on the die cavities. For a casting to be successful the mold cavity must retain its shape until the metal has cooled and fully solidified.

Die coatings protect the steel against the abrasive effect of molten metal. It can obtain castings with higher dimensional accuracy and lower. For this reason semi-permanent mold castings are also available.

Its these molds that distinguish the processes from sand casting where a new cavity is formed in sand every cycle. Surface of the sand castings is normally rough with surface impurities for which a machining allowance is included. The metal typically a non-ferrous alloy such as aluminum or zinc is melted in.

For companies that have a sufficient lead time and are able to front the higher cost of having their molds made out of steel die casting is going to save them money in the. The short answer is yes the casting sand in sand casting can be reused. Die casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mould cavityThe mold cavity is created using two hardened tool steel dies which have been machined into shape and work similarly to an injection mold during the process.

As we reviewed above die casting uses a metal mold while sand casting uses a mold made out of sand. The advantages of die casting that the die can be used multiple times die casting has the capability for rapid production. Pure sand breaks apart easily but molding sand contains bonding material that increases its ability to resist heat and hold shape.

Die Casting In this process metal is forced into the mold. This article has distinguished certain characteristics common across both methods and has compared them to show where each casting procedure is be. The biggest and most obvious difference between the die and sand casting process is the materials used to form the molds.

Die casting is a manufacturing process that can produce geometrically complex metal parts through the use of reusable molds called dies. The die casting process involves the use of a furnace metal die casting machine and die. And while investment castings can make parts weighing only fractions of an ounce they are limited in terms of the size and weight of parts.

It is most commonly used in sand casting die casting and injection molding. The final casting process is sand casting. One of the biggest benefits of this method is that the casting sand can be reused.

In most cases the sand is recycled and. The major difference between the two steel die techniques is how the metal gets into the tooling. Permanent mold casting can create stronger castings than die casting but they can be difficult to remove from the final product.

The die refers to the steel mold created in the shape the product will be made. Explain why process such as sand shell molding and investment casting can produce parts with greater shape complexity than. The mold is then reclosed and prepared for another pour.

Die casting is a process where liquid or molten metal is forced into a die under high pressure. The primary difference between die casting and sand casting is in the mold. The metal mold has large thermal conductivity and heat capacity fast cooling speed dense casting structure and mechanical properties about 15 higher than sand casting.

The process of die casting is also different from the sand casting process. While there are fundamental differences in the processes for creating a die-casted product and a sand-casted product both have legitimate applications in commercial manufacturing. The biggest difference between present day casting and the process of a hundred years ago is the amount of planning precision design and tolerance achieved through computerization and automation.

11 rows Required machinery for die casting cost of producing molds from specialty steel create higher. Hot Chamber Die Casting Method A characteristic feature of hot chamber die casting machines is that the casting chamber is constantly in contact with the liquid alloy. Firstly the molten metal is poured into a shot chamber.

Die Casting Process is different from the Sand casting process with respect to the mold only. Most die castings are made from non-ferrous metals specifically zinc copper aluminium. These molds have expendable cores making them more manageable and less costly to remove.

Castings are produced by pouring liquid metal into a mold cavity. The difference between the two processes lies in the structure of the casting chamber as described below. Sand casting is one of the oldest manufacturing methods and the use of sand has certain advantages over other casting methods such as plaster or die casting.

Die Casting Vs Sand Casting What S The Difference

Investment Casting Vs Die Casting 7 Considerations When Choosing A Process

Comments

Post a Comment